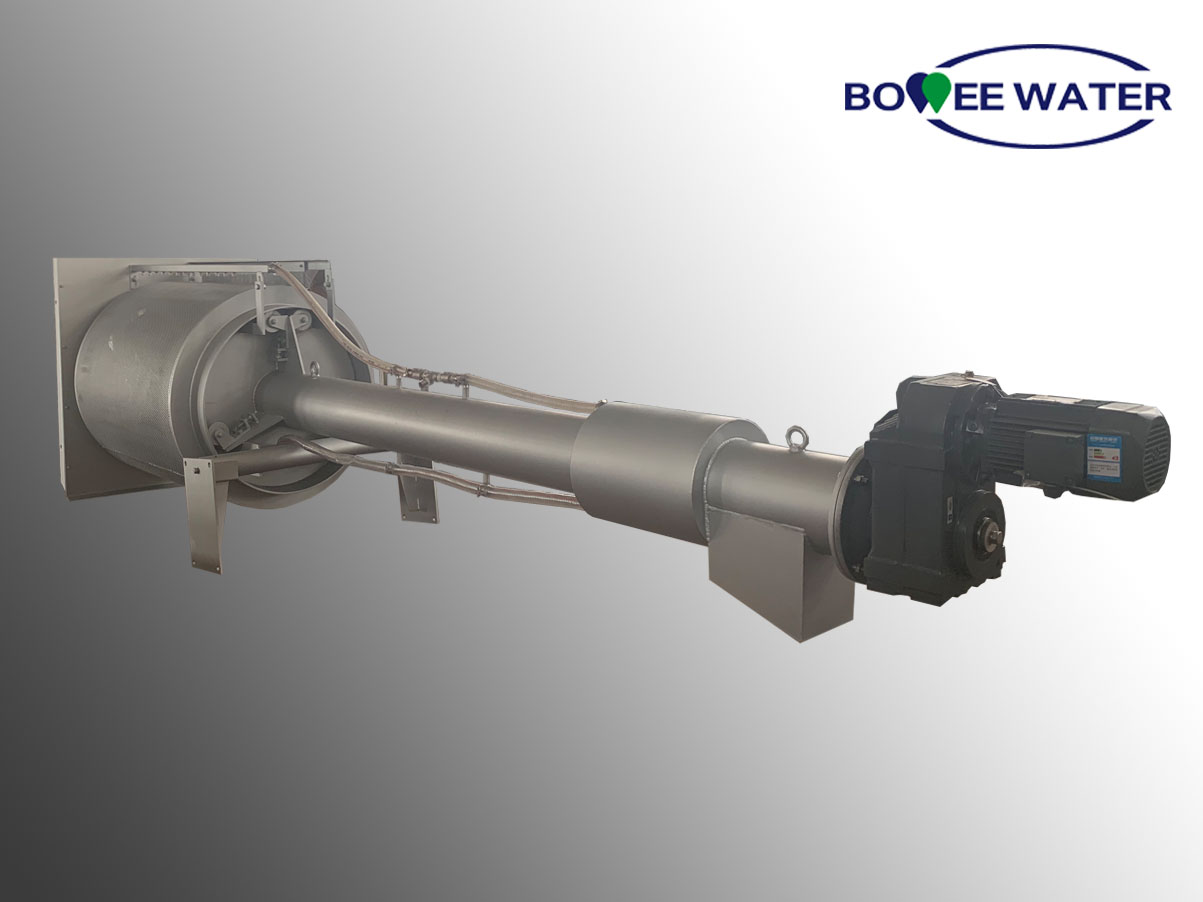

Rotary drum screen(in channel) is a new type of product developed & produced by BOWEE which absorbed foreign advanced technology & combined actual condition of domestic water treatment.

Specifications:

Dimension: Customized

Material: SS304, SS316 or Customized

Mesh opening: 0.5-10mm

Opening type: Wedge wire or Perforated

Self-cleaning type: Brush and spraying water

Inclined angle: 35°

Motor brand: First-class motor, Nord or SEW is optional